A Blowing Success

The location of the fan

Capacity to replenish the air several times per hour

Ensuring the noise factor was kept within the required decibel level for a residential area.

The initial design featured a roof mounted install with 5 branches extending the length of the foundry. This option offered a straightforward installation however IXL were concerned about the potential noise particularly as the foundry, which is sited in a residential area, sometimes operates past 9pm. Despite our assurances that our silencers would ensure the fan operated within the required decibel level, their concern was that any complaints would result in a costly relocation of the system.

Their next option was to install the system in a restricted space at the rear of building (solving the neighbourhood noise issues) however the size of the fan and ducting required made this impractical.

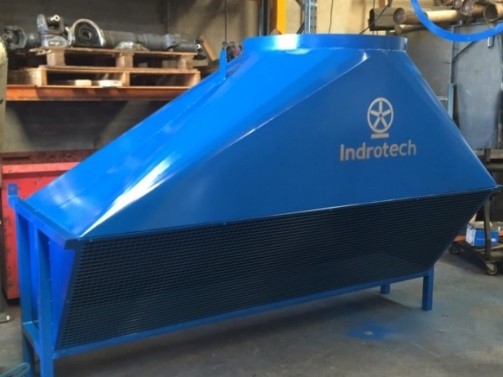

Finally it was decided to site the fan at the top of the ceiling inside the foundry – solving the potential issues of noise and space limitations. The downside was the added cost and difficulty of the installation – requiring internal scaffolding and working outside the foundry hours to minimise the interruption to business. Once the location had been confirmed the design was finalised. We fabricated a 56” diameter heavy duty belt driven axial fan with inlet and discharge silencers, plus mounting feet to assist in the installation. The installation itself took several weeks but once the fan was commissioned we arranged a site visit.

The positive impact of the fan was immediately evident as we climbed to the top of one of the foundry’s hoppers to get a closer look at the system – being able to breathe easily and talk normally in a previously harsh environment. It has been a pleasure working with the team at IXL Metal Castings.

“Since we installed the Ventilation Fan into the highest point of our Casting Plant Building some months ago, we have experienced much change in our Internal Environment. The accumulation of hot air produced by melting, pouring and cooling castings now by natural convection makes its way to the high points and is quickly extracted from within. We are able to (and it is necessary to) leave doors open, fix shutters and vents open to allow sufficient in rush of fresh air to replace that what has been extracted. Operator comforts are at a much higher standard and a very pleasing result. Thank you Dennis & the team at Indrotech for your design and supply assistance”.

Jim Miller, Engineering Services Supervisor at IXL Metal Castings

Quality guaranteed, Certificate of Balance upon request.

Dynamic Fans of high speed rotating components increases bearing life, achieves smoother running conditions, increases service life and enhances the quality of the finished product.

To ensure quality workmanship, Indrotech periodically service and calibrate all Fans machines to continue to provide optimal productivity, accuracy and reliability.