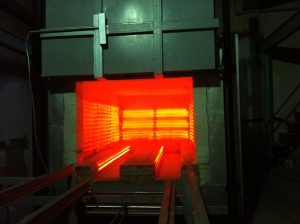

Cladded Fans for Industrial Furnaces and ovens

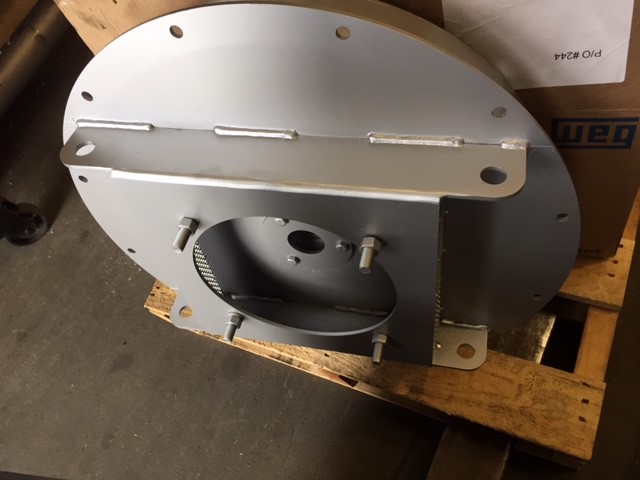

The solution, a cladded fan. This type of fan has an insulated area between the two, inner and outer fan casings. This reduces the temperature of the running fan significantly. It also reduces the noise drastically.

You have a cladded fan when the is temperature and noise reduction is an issue. There are also safety reasons. These fans are used in industrial furnaces and Ovens. Other reasons for having a cladded fan casing is in a situation such as a direct of which will reduce radiant heat to the drive motor.

Fans for many applications

Whether we have a clean air fan, a material conveying fan, a hot recirculating fan or a special fan such as this. Indrotech has a solution for each application.

We have over a decade of experience as an Industrial Fans Supplier, Manufacturer & Repair. Indrotech Melbourne design in-house an extensive range of industrial furnace and oven fans. From dust and fume control to high-temperature recirculation and exhaust applications.